Disinfection - a must in many areas

Disinfectant monitoring for safe wastewater disinfection

Disinfectant measurement is essential for safe water disinfection in many applications such as legally required disinfection of wastewater, disinfection of drinking water, seawater desalination, in power plants, disinfection of packaged food or cans and multiple-use bottles, and in swimming pool water.

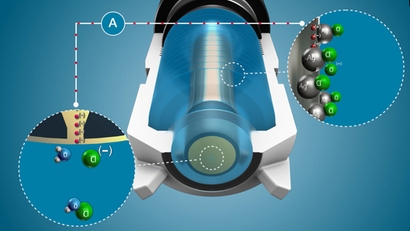

The video highlights the benefits of the Endress+Hauser disinfection sensor portfolio by taking a closer look at the potable water production where chlorine-based reagents are used as disinfectants.

Disinfection in drinking water

Potable water distribution networks must deliver safe, high-quality water to consumers. A small amount of free chlorine or chlorine dioxide is dosed at the waterworks outlet to prevent recontamination of the treated water during transport. Here, disinfectants are applied in very low concentrations and Memosens CCS51E free chlorine and CCS50E chlorine dioxide sensors are used. For free chlorine, pH compensation with CPS31E is useful to secure effective disinfection.

Disinfection in cooling water

Cooling is required everywhere in the production industry be it in energy generation or food production. The cooling medium is often process or surface water. To maximize the available cooling capacity, it is important to minimize the spread of biofilms. Typically, a disinfectant is added to the cooling water to prevent formation of bacterial lawns in the cooling pipes.

Chlorine dioxide has proven successful in these kinds of applications since it directly degrades biofilms and is active over a wide pH range even if corrosion inhibitors are added that increase the pH value. It is especially suitable for open recooling plants to ensure compliance with strict regulations such as the 42. BImSchV or VDI2047 Blatt2.

Disinfection in wastewater

Normally, the outlet water is discharged into natural waters at the end of wastewater treatment. Especially in summer, these natural waters might have a very low water level and mainly consist of outlet water of WWTPs. That's why the outlet water is often disinfected. In some wastewater treatment plants, the water is disinfected to achieve maximum purity.

In these cases, a chlorine tank (free chlorine present in water as hypochlorous acid (HOCl)) is installed and chlorine is added to the process by a dosing pump. In industrial wastewater treatment plants, concentration of the strongly disinfecting HOCl is important, in municipal plants concentration of available free chlorine, i.e. the sum of HOCl and OCl- is more decisive. The latter often requires a pH compensation of the displayed chlorine concentration.

Seawater and desalination

Water purification by reverse osmosis treatment, such as seawater desalination or just ground, lake or river water purification uses dosing of a disinfectant like HOCl in the water intake to inhibit organic growth of shellfish or other forms of biological growth.

After the pretreatment steps, before the water is passing over the reverse osmosis modules, the residual disinfectant is reduced by dosing sodium sulfide because any kind of disinfectant would damage the expensive osmosis modules. In that step, a very reliable measurement is key and the sensor must not passivate when no disinfectant is present, since the measuring system normally measures nothing. Only in a case of breakthrough it needs to detect the disinfectant to safeguard the modules.

For an overview over the applications, their measuring ranges and suitable sensors, click here.