What is the best sampling method for my operation?

Which do I choose: Peristaltic, Vacuum or In-Line and why?

The difference is found in the sample velocity, meaning how fast the air can be removed from the sample and it can be transported to the sample container. The speed and efficiency at which these actions are completed help to assure the user that an accurate sample has been taken.

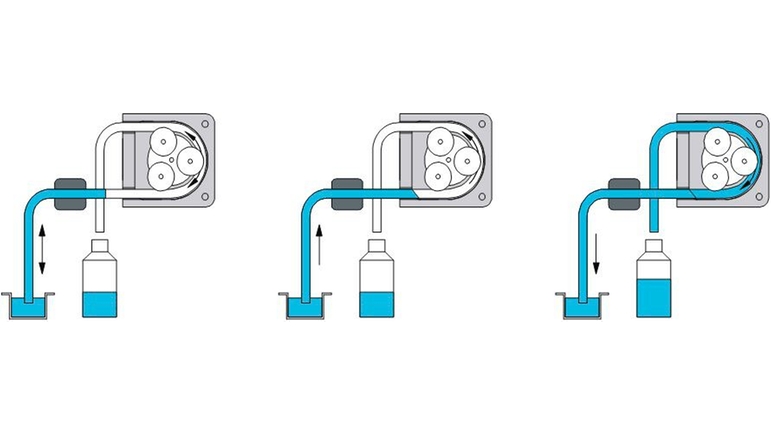

Peristaltic: The rollers of a peristaltic pump rotate and deform the pump tubing. This creates a vacuum and suction effect. The fluid is conveyed in the suction line in the direction of rotation of the rollers.

Purge & Rinse | Lift & Dose | Purge

Peristaltic pump samplers are convenient for short intake and suction heights and variable sample volumes. This sampling method is ideal when trying to sample corrosive or harsh liquids as there is no contact occurring through the tube.

Vacuum: The vacuum pump pushes air into the chamber causing the liquid to be purged out of the intake hose. The fluid is drawn into a chamber by the vacuum pump until the sample touches the electrodes. The dosing system is vented to atmospheric pressure so the excess sample siphons back into the sample source line. The measured sample volume is then distributed into the bottles.

Vacuum pump systems provide accurate as well as repeatable sample volumes in a higher level of performance for more demanding applications. This is usually the preferred method for measurement of fatty, cloudy or greasy liquids.

Inline Assembly: The inline assembly is mounted directly on the process pipe from which the sample is to be taken. A sample plunger is forced by means of air pressure into the pipe where it is filled with fluid. When the sample plunger is pressed back into the assembly, the sample flows into the bottle. As an option, this can take place under pressure and with subsequent cleaning. After a defined period, the system assumes an operational readiness state again

The inline assembly is preferred when the sampling needs to be done in pressurised pipes and when there is no open channel for collection. This also makes the Autosampler suitable for use in industrial applications where detection of anomalies in processes are required.

With the 3 types of sampling methods available Endress+Hauser is able to provide you with a solution for your processes.